设计说明书

总字数:19000+

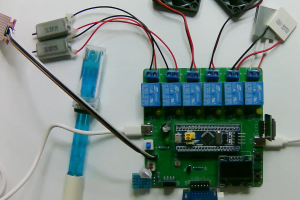

本论文旨在探讨并实现一种基于物联网技术的智能水产养殖管理系统,使用STM32F103C8T6单片机作为核心控制器。该系统旨在提升水产养殖的效率和可控性,通过多传感器检测和智能控制,实现对水产养殖环境的精细监测与调控。系统具备以下功能:温湿度检测、温湿度控制、光照检测、光照控制、CO2浓度检测、CO2浓度控制、pH值检测、pH值控制、液位检测、液位控制、阈值设置、数据显示和远程控制。通过DHT11传感器,系统能够实时检测环境的温湿度情况。当温度超过设定范围时,通过继电器控制制冷片进行降温;当温度过低时,通过继电器控制加热片进行升温;湿度过高时,继电器控制风扇进行除湿。光敏电阻用于监测光照值,当光照不足时,系统通过三极管控制LED灯进行补光。SGP30传感器监测CO2浓度,当超过设定值时,继电器控制风扇进行通风。pH检测模块用于检测水质的pH值,超过设定值时,继电器控制水泵进行酸碱液的中和。液位检测模块监测液位,低于设定值时,继电器控制水泵进行加水。系统的智能性体现在阈值的设置和远程控制方面。用户可以通过按键设置各个参数的阈值,根据实际需求进行个性化设定。OLED显示屏实时展示各项测量数据,方便用户随时了解养殖环境状态。通过ESP8266模块,系统可以实现联网功能,将监测数据传送到手机端,用户可以远程监控和控制继电器开关,从而实现对养殖环境的远程管理。本研究成果对水产养殖领域具有实际应用价值,通过引入物联网技术,提升了养殖管理的智能化水平,有效减少了人力成本,提高了生产效率。未来,可以进一步探索优化算法和系统稳定性,使系统更加智能化、稳定性更强,为水产养殖行业的可持续发展提供有力支持。

关键词:智能水产养殖;物联网技术;环境监测与控制;远程管理;水质检测与调控

Abstract

The purpose of this paper is to explore and implement an intelligent aquaculture management system based on Internet of Things (IoT) technology, using STM32F103C8T6 microcontroller as the core controller. The system aims to enhance the efficiency and controllability of aquaculture by utilizing multiple sensors for detection and intelligent control, achieving precise monitoring and regulation of aquaculture environment. The system features functions including temperature and humidity detection, temperature and humidity control, light intensity detection, light intensity control, CO2 concentration detection, CO2 concentration control, pH value detection, pH value control, liquid level detection, liquid level control, threshold setting, data display, and remote control.With the DHT11 sensor, the system can detect real-time temperature and humidity conditions. When the temperature exceeds the preset range, the cooling unit is activated through a relay to lower the temperature; when the temperature falls below the minimum value, the heating unit is activated to raise the temperature; excessive humidity triggers the fan via a relay for dehumidification. The photosensitive resistor is used to monitor light intensity, activating LED lights through a transistor when insufficient light is detected. The SGP30 sensor monitors CO2 concentration, and if it exceeds the set value, a relay controls the fan for ventilation. A pH detection module is used to monitor the pH value of the water; when it surpasses the designated value, a relay controls the pump to adjust the acidity or alkalinity. A liquid level detection module monitors liquid levels, and if they fall below the set value, a relay controls the pump for water replenishment.The system’s intelligence is demonstrated in threshold setting and remote control. Users can customize threshold values for various parameters through buttons, meeting specific requirements. An OLED display screen provides real-time measurement data, allowing users to monitor the aquaculture environment status. Through the ESP8266 module, the system achieves network connectivity, transmitting monitoring data to a mobile phone, enabling remote monitoring and relay control. This study’s outcomes hold practical value for the aquaculture industry. By incorporating IoT technology, it enhances the intelligence of aquaculture management, effectively reducing labor costs and improving productivity. Future research can delve into optimizing algorithms and enhancing system stability, further enhancing intelligence and stability, thereby providing robust support for the sustainable development of the aquaculture industry.

Keywords: Intelligent aquaculture; Internet of Things technology; environmental monitoring and control; remote management; water quality detection and regulation.

目录

基于物联网的智能水产养殖管理系统设计与实现

摘要

Abstract

第一章 绪论

1.1课题设计背景与意义

1.2国内外发展历程

1.3研究目标及预期功能

第二章 设计思路与方案选择

2.1 主要元器件选择

2.1.1 主控芯片选择

2.1.2 光照强度检测模块方案选择

2.1.3 温湿度检测模块方案选择

2.1.4 CO2监测模块方案选择

2.2整体设计方案

第三章 硬件设计

3.1主控电路模块

3.2光照强度检测电路模块

3.3 温湿度检测电路模块

3.4 PH值监测电路模块

3.5 CO2监测电路模块

3.6 水位监测电路模块

3.7 显示电路模块

3.8 继电器电路模块

3.9 独立按键电路模块

3.10 WiFi无线传输模块

第四章 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 温湿度检测模块子流程

4.5 OLED显示流程设计

4.6 WiFi模块子流程设计

第五章 实物测试

5.1整体实物测试

5.2环境温度检测实物测试

5.3 环境湿度检测实物测试

5.4 光照强度监测实物测试

5.5 PH值监测实物测试

5.5 CO2检测实物测试

5.7液位检测实物测试

第七章 总结与展望

致谢

参考文献

附录

附录一 原理图

附录二:PCB

附录三:主程序

购买后可查看具体内容!