设计说明书

总字数:15000+

当今社会对于智能家居系统的需求逐渐增加,本毕业设计旨在设计并实现一款基于STC89C52单片机的智能鞋柜自动控制系统。该系统通过集成多种传感器和控制模块,能够实时监测鞋柜内温湿度、氨气浓度以及门的状态,并根据检测结果自动进行加热、除湿、紫外线杀菌、通风等操作,以确保鞋柜内的鞋品保持干燥、清洁和舒适。系统的核心控制单元采用STC89C52单片机,通过编程实现各种功能模块的协同工作。具体功能包括:温湿度控制:通过DHT11传感器监测鞋柜内温湿度,当湿度超过设定最大值时,系统自动启动加热片进行干燥,并通过风扇排除湿气。在加热过程中,如果温度超过设定最大值,自动停止除湿操作,确保温度在安全范围内。氨气检测与处理:借助MQ-135传感器监测鞋柜内氨气浓度,当浓度异常升高时,系统自动启动紫外线杀菌操作,同时启动风扇进行除臭,保持鞋柜内空气清新。门状态检测:通过霍尔传感器检测鞋柜门的开闭状态,当门打开时,系统自动开启照明,同时关闭紫外线杀菌功能,提供良好的照明环境。用户交互与设置:系统通过按键实现湿度和氨气最大值的设定,用户可以手动控制消毒灯、除湿、通风等功能的开关,同时切换不同的工作模式,以满足不同需求。显示与反馈:LCD1602液晶显示屏实时显示鞋柜内温湿度、氨气浓度等测量值,同时显示当前工作状态和模式,为用户提供直观的反馈信息。本设计旨在提高鞋柜的智能化程度,提供便捷、舒适、卫生的使用体验。通过系统的设计与实现,将单片机、传感器和控制技术相结合,达到了智能家居系统的基本目标,为未来智能家居技术的发展提供了一定的参考与借鉴。

关键词:智能鞋柜;单片机控制;温湿度监测;氨气检测;自动控制系统;用户交互界面

The increasing demand for smart home systems in today’s society has led to the aim of this graduation project: to design and implement an intelligent shoe cabinet automatic control system based on the STC89C52 microcontroller. This system integrates various sensors and control modules to real-time monitor the temperature, humidity, ammonia gas concentration, and door status inside the shoe cabinet. It automatically performs operations such as heating, dehumidification, ultraviolet germicidal irradiation (UVGI), and ventilation based on the detection results, ensuring the shoes inside the cabinet remain dry, clean, and comfortable.The core control unit of the system adopts the STC89C52 microcontroller, which programs the collaborative operation of various functional modules. Specific functionalities include:Temperature and Humidity Control: Using the DHT11 sensor to monitor the temperature and humidity inside the shoe cabinet, the system automatically activates the heating element for drying when the humidity exceeds the preset maximum value. A fan is used to expel moisture. During heating, if the temperature surpasses the preset maximum value, the dehumidification operation stops automatically to maintain a safe temperature range.Ammonia Gas Detection and Treatment: With the MQ-135 sensor, the system detects abnormal increases in ammonia gas concentration inside the shoe cabinet. In such cases, the system triggers UVGI and initiates the fan for deodorization, ensuring fresh air within the cabinet.Door Status Detection: Using the Hall sensor, the system detects the open/close status of the shoe cabinet door. When the door is opened, the system automatically activates the lighting and deactivates the UVGI function, providing proper illumination.User Interaction and Settings: The system allows users to set the maximum humidity and ammonia gas concentration values using buttons. Users can manually control the disinfection light, dehumidification, ventilation, etc., and switch between different operation modes to meet varying needs.Display and Feedback: The real-time display on the LCD1602 screen shows measurements such as internal temperature, humidity, ammonia gas concentration, and current operational mode. This provides users with intuitive feedback on the system’s status.This design aims to enhance the intelligence of the shoe cabinet, offering convenient, comfortable, and hygienic user experiences. By integrating microcontroller, sensor, and control technologies, the design achieves the fundamental goals of a smart home system. It serves as a reference and inspiration for the future development of smart home technology.

Keywords: Smart shoe cabinet; Microcontroller control; Temperature and humidity monitoring; Ammonia gas detection; Automatic control system; User interaction interface..

目录

基于单片机的多功能智能室内空气质量监测与控制系统

摘要

Abstract

第一章 绪论

1.1课题设计背景与意义

1.2国内外发展历程

1.3研究目标及预期功能

第二章 设计思路与方案选择

2.1 主要元器件选择

2.1.1 主控芯片选择

2.1.2 温湿度检测模块方案选择

2.1.3 烟雾浓度检测模块方案选择

2.1.4 显示模块方案选择

2.2整体设计方案

第三章 硬件设计

3.1主控电路模块

3.2 温湿度检测电路模块

3.3 PM2.5检测电路模块

3.4 烟雾检测电路模块

3.5 甲醛检测电路模块

3.6 甲苯检测电路模块

3.7 TVOC检测电路模块

3.8 显示模块电路模块

3.9 声光报警电路模块

3.10 蓝牙模块电路模块

3.11 独立按键电路模块

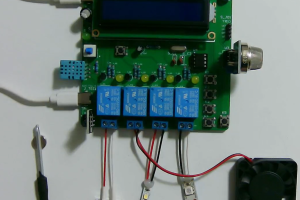

3.12 继电器电路模块

第四章 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 温湿度检测模块子流程

4.5 蓝牙模块子流程

4.6OLED显示流程设计

第五章 实物测试

5.1整体实物测试

5.2 PM2.5检测实物测试

5.3 烟雾检测实物测试

5.4 甲醛检测实物测试

5.5 甲苯检测实物测试

5.6 温湿度检测实物测试

5.7 TVOC实物测试

5.8 远程测控实物测试

第六章 总结与展望

6.1 总结

6.2 展望

致谢

参考文献

附录

附录一 原理图

附录二:PCB

附录三:主程序

购买后可查看具体内容!