设计说明书

总字数:21000+

摘 要

随着纺织产业的快速发展,纺织仓库的安全监测变得尤为重要。针对纺织仓库可能存在的火灾、烟雾、可燃气体泄露等安全隐患,提出了一种基于STM32的纺织仓库防火控制系统设计。

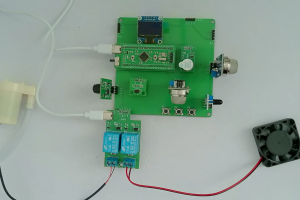

系统采用STM32F103C8T6单片机作为主控芯片,通过火焰传感器检测是否发生明火,一旦检测到明火,系统立即通过继电器控制水泵进行灭火,并启动声光报警;通过MQ-2烟雾传感器监测仓库内的烟雾浓度,当烟雾浓度超过预设阈值时,系统控制风扇通风,并触发声光报警;通过MQ-5可燃气体传感器监测仓库内的可燃气体浓度,一旦浓度超标,控制风扇通风并报警;通过DS18B20温度传感器实时监测仓库温度,当温度超过设定值时,也采取通风并报警的措施;通过人体热释电模块用于监测监控区域是否有人员闯入,当有人闯入且系统处于布防状态时,立即触发声光警报。此外,系统还具备通过按键设置各监测参数的阈值、手动控制水泵、风扇以及布防撤防的功能。

测试表明,该系统运行稳定,能够实时监测纺织仓库内的多种安全隐患,并采取相应的应急措施,有效提高了仓库的防火安全性能。为纺织产业的安全生产提供了有力保障。

关键词:STM32;纺织仓库;安全监测;火焰检测;烟雾浓度监测

With the rapid development of the textile industry, the safety monitoring of textile warehouses has become particularly important. A fire control system design for textile warehouses based on STM32 is proposed to address potential safety hazards such as fire, smoke, and combustible gas leaks.

The system uses STM32F103C8T6 microcontroller as the main control chip, and detects whether there is an open flame through a flame sensor. Once an open flame is detected, the system immediately controls the water pump through a relay to extinguish the fire and starts an audible and visual alarm; Monitor the smoke concentration in the warehouse through the MQ-2 smoke sensor. When the smoke concentration exceeds the preset threshold, the system controls the fan ventilation and triggers an audible and visual alarm; Monitor the concentration of combustible gases in the warehouse through MQ-5 combustible gas sensors. Once the concentration exceeds the standard, control the fan ventilation and sound an alarm; Real time monitoring of warehouse temperature through DS18B20 temperature sensor. When the temperature exceeds the set value, ventilation and alarm measures are also taken; The human thermoelectric module is used to monitor whether there are personnel entering the monitoring area. When someone enters and the system is in the armed state, an audible and visual alarm is immediately triggered. In addition, the system also has the functions of setting threshold values for various monitoring parameters through buttons, manually controlling water pumps and fans, and deploying and disarming.

Tests have shown that the system runs stably, can monitor various safety hazards in the textile warehouse in real time, and take corresponding emergency measures, effectively improving the fire safety performance of the warehouse. This provides strong guarantees for the safety production of the textile industry.

Key words:STM32; Textile factory warehouse; Safety monitoring; Flame detection; Smoke concentration monitorings

目 录

第1章 引言

1.1 选题的目的及意义

1.2 国内外研究现状

1.2.1 国内研究现状

1.2.2 国外研究现状

1.3 研究目标

1.4 研究内容

第2章 系统方案设计

2.1 系统总体架构

2.2 STM32F103C8T6单片机

2.3 温度传感器

2.4 火焰传感器

2.5 MQ-2烟雾模块

2.6 MQ-5可燃气体模块

2.7 人体热释电模块

2.8 显示模块

2.9 按键模块

2.10 声光报警模块

2.11 继电器模块

第3章 系统硬件设计

3.1 硬件电路设计总图

3.2 主控电路图

3.3 电源电路

3.4 温度采集模块电路

3.5 火焰采集电路

3.6 烟雾采集电路

3.7 可燃气体采集电路

3.8 人体采集电路

3.9 按键电路

3.10 显示电路

3.11 声光报警电路

3.12 继电器电路

3.13 硬件电路PCB设计总图

第4章 系统软件设计

4.1 主程序流程图设计

4.2 温度检测模块子流程

4.3 烟雾检测模块子流程

4.4 火焰检测模块子流程

4.5 按键模块子流程设计

4.6 OLED显示流程设计

第5章 系统测试

5.1 仿真测试

5.1.1 整体仿真测试测试

5.1.2 火焰测控仿真测试

5.1.3 烟雾测控仿真测试

5.1.4 可燃气体测控仿真测试

5.1.5 温度测控仿真测试

5.1.6 防盗测控仿真测试

5.2 实物测试

5.2.1 火焰测控实物测试

5.2.2 烟雾测控实物测试

5.2.3 可燃气体测控实物测试

5.2.4 温度测控实物测试

5.2.5 防盗测控实物测试

第6章 结论

参考文献

附 录

附录1.原理图

附录2 PCB

附录3 主程序源代码

致 谢

购买后可查看具体内容!