设计说明书

总字数:16000+

摘要

在工厂车间的日常生产中,工具的规范管理是保障生产效率和安全生产的重要环节。传统工具柜缺乏有效的实时监测手段,工具丢失、挪用等问题时有发生,不仅影响生产进度,还可能因工具缺失带来安全隐患。因此,研发一种能实时监测工具状态、实现规范管理的智能监测工具柜十分必要。

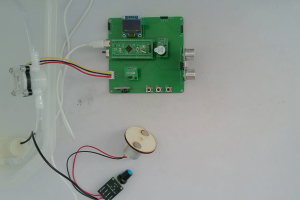

本设计提出了一种基于 STM32F103C8T6 单片机的工厂车间监测工具柜。系统主要功能包括:通过三个红外避障传感器分别检测螺丝刀、扳手、剪刀是否在对应位置上;借助 OLED 显示屏实时显示三种工具的在位状态及工具箱的开关状态;当检测到工具被拿走时,触发蜂鸣器鸣响三声进行提醒,同时启动定时功能记录工具从拿走到归还的时间;通过 ESP8266-WiFi 模块将工具在位状态和工具箱开关状态传输至手机端,实现远程监控;管理人员需通过 RFID-RC522 刷卡,经 ULN2003A 驱动四相五线步进电机模拟开启工具箱。

该监测工具柜的作用在于,为工厂车间工具管理提供了一种智能化、便捷化的解决方案。通过实时监测、自动提醒和远程监控,能够有效减少工具丢失情况,规范工具使用流程,提高工具管理效率,为车间生产的有序进行提供保障。

关键词:单片机;监测工具柜;红外检测;远程监控;RFID 刷卡

Factory workshop monitoring tool cabinet

Abstract

In the daily production of factory workshops, standardized management of tools is an important link to ensure production efficiency and safety. Traditional tool cabinets lack effective real-time monitoring methods, and problems such as tool loss and misappropriation often occur, which not only affects production progress but may also pose safety hazards due to tool shortages. Therefore, it is necessary to develop an intelligent monitoring tool cabinet that can monitor tool status in real time and achieve standardized management.

This design proposes a factory workshop monitoring tool cabinet based on STM32F103C8T6 microcontroller. The main functions of the system include: detecting whether the screwdriver, wrench, and scissors are in the corresponding positions through three infrared obstacle avoidance sensors; Real time display of the in place status of three tools and the on/off status of the toolbox using OLED display screen; When the tool is detected to have been taken away, the buzzer will sound three times as a reminder, and the timer function will be activated to record the time from taking the tool away to returning it; By using the ESP8266 WiFi module to transmit the tool’s in place status and toolbox switch status to the mobile phone, remote monitoring can be achieved; Management personnel need to swipe their card through RFID-RC522 and simulate the opening of the toolbox using a four phase five wire stepper motor driven by ULN2003A.

The purpose of this monitoring tool cabinet is to provide an intelligent and convenient solution for tool management in factory workshops. Through real-time monitoring, automatic reminders, and remote monitoring, it is possible to effectively reduce tool loss, standardize tool usage processes, improve tool management efficiency, and provide guarantees for orderly production in the workshop.

Keywords:microcontroller; Monitoring tool cabinet; Infrared detection; Remote monitoring; RFID card swiping

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 红外避障检测模块电路设计

3.4 OLED 显示模块电路设计

3.5 声光报警模块电路设计

3.6 ESP8266-WiFi 模块电路设计

3.7 RFID-RC522 模块电路设计

3.8 ULN2003A 驱动与步进电机模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 OLED显示流程设计

4.4 RFID模块子流程设计

4.5 步进电机子流程设计

4.6 WiFi模块子流程设计

5 实物制作与功能测试

5.1 实物制作

5.2 红外避障检测功能测试

5.3 OLED 显示功能测试

5.4 声光报警功能测试

5.5 ESP8266-WiFi 通信功能测试

5.6 RFID 刷卡与步进电机控制功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!