设计说明书

总字数:16000+

摘要

在矿井生产环境中,温湿度异常、烟雾聚集及瓦斯泄漏等问题直接威胁作业人员的生命安全。温度过高可能引发设备故障或火灾,湿度过大影响作业环境,烟雾和瓦斯浓度超标则易导致爆炸或中毒事故,这些隐患若不能及时监测和干预,将造成严重的安全后果。因此,研发一种能实时监测矿井环境参数并智能调控通风的系统十分必要。

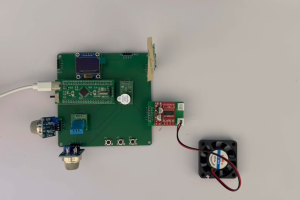

本设计提出一种基于 STM32F103C8T6 单片机的矿井安全通风系统。系统主要功能包括:通过DHT11 传感器检测矿井环境的温湿度;借助MQ-2 传感器监测烟雾浓度;利用MQ-4 传感器检测瓦斯浓度;当温度、湿度、烟雾或瓦斯中任意参数大于最大值时,触发声光报警,同时控制风扇高速转动;参数处于最大值与最小值之间时,风扇根据浓度自动调节转速;参数均小于最小值时,风扇停止运行;用户可通过按键设置温湿度、烟雾及瓦斯浓度的最大和最小值阈值;通过OLED 显示屏实时显示各项监测数据;同时,系统通过4G 模块将检测数据上传至阿里云平台,手机端可远程设置参数并控制风扇转动。

该系统的作用在于,为矿井生产提供了智能化的安全监测与通风调控方案。通过实时监测、自动响应和远程管理,能够及时预警环境风险,优化通风效果,保障矿井作业安全,降低事故发生概率。

关键词:单片机;矿井安全;通风系统;环境监测;智能调控

Design of Mine Safety Ventilation System

Abstract

In the production environment of mines, issues such as abnormal temperature and humidity, smoke accumulation, and gas leakage directly threaten the safety of workers. Excessive temperature may cause equipment failure or fire, high humidity affects the working environment, and excessive smoke and gas concentration can easily lead to explosions or poisoning accidents. If these hidden dangers are not monitored and intervened in a timely manner, they will cause serious safety consequences. Therefore, it is necessary to develop a system that can monitor mine environmental parameters in real time and intelligently regulate ventilation.

This design proposes a mine safety ventilation system based on STM32F103C8T6 microcontroller. The main functions of the system include: detecting the temperature and humidity of the mine environment through DHT11 sensors; Monitor smoke concentration with MQ-2 sensor; Using MQ-4 sensors to detect gas concentration; When any parameter in temperature, humidity, smoke or gas exceeds the maximum value, an audible and visual alarm is triggered, and the fan is controlled to rotate at high speed; When the parameter is between the maximum and minimum values, the fan automatically adjusts its speed according to the concentration; When all parameters are below the minimum value, the fan stops running; Users can set the maximum and minimum threshold values for temperature, humidity, smoke, and gas concentration through buttons; Real time display of various monitoring data through OLED display screen; At the same time, the system uploads the detection data to the Alibaba Cloud platform through the 4G module, and the mobile end can remotely set parameters and control the fan rotation.

The function of this system is to provide intelligent safety monitoring and ventilation control solutions for mine production. Through real-time monitoring, automatic response, and remote management, environmental risks can be warned in a timely manner, ventilation effects can be optimized, mine operation safety can be guaranteed, and the probability of accidents can be reduced.

Keywords: microcontroller; Mine safety; Ventilation system; Environmental monitoring; Intelligent regulation

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 温湿度检测模块电路设计

3.4 烟雾检测模块电路设计

3.5 瓦斯检测模块电路设计

3.6 显示模块电路设计

3.7 按键模块电路设计

3.8 声光报警模块电路设计

3.9 风扇驱动模块电路设计

3.10 4G 通信模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 温湿度检测模块子流程设计

4.5 OLED显示流程设计

4.6 直流电机速度调节子流程设计

4.7 4G模块联网子流程设计

5 实物制作与功能测试

5.1 实物制作

5.2 环境参数检测及显示功能测试

5.3 风扇调速功能测试

5.4 声光报警功能测试

5.5 参数设置功能测试

5.6 远程通信功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!