设计说明书

总字数:14000+

摘要

在纺织生产过程中,筒子纱的重量控制与环境监测对保证产品质量、提高生产效率至关重要。传统的筒子纱管理主要依赖人工称重和环境巡查,不仅效率低下、误差较大,而且难以实时掌握重量超标情况,容易影响后续加工环节的稳定性,无法满足现代化纺织生产的精准化需求。

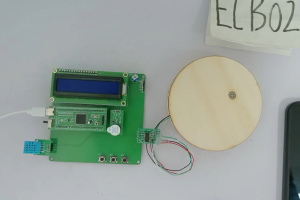

基于 STC89C52 单片机的筒子纱监测系统,整合了 HX711 称重模块、DHT11 温湿度传感器、3 个独立按键、LCD1602 显示屏、ECB02 蓝牙模块及声光报警装置,实现了筒子纱重量与环境的自动化监测及智能预警。系统核心功能包括:通过 HX711 称重模块实时获取筒子纱重量;借助 DHT11 传感器检测当前环境的温湿度;当监测到重量大于预设最大值时,触发声光报警;支持通过 3 个独立按键设置重量最大值;利用 LCD1602 显示屏实时显示温湿度和称重测量值;通过 ECB02 蓝牙模块将重量值发送到手机端,当重量达到最大值时发送 “重量过高” 的预警信息。

该系统的实现,有效提升了筒子纱监测的自动化水平,减少了人工干预带来的误差,确保了重量控制的精准性和环境监测的实时性,为纺织生产提供了高效、可靠的解决方案,同时为同类纺织监测设备的研发提供了参考,具有较高的实际应用价值。

关键词:STC89C52;筒子纱;监测系统;传感器;重量控制;蓝牙通信

ABSTRACT

In the textile production process, weight control and environmental monitoring of yarn packages are crucial for ensuring product quality and improving production efficiency. Traditional yarn package management mainly relies on manual weighing and environmental inspections, which are not only inefficient and error-prone but also make it difficult to grasp weight overrun situations in real-time, easily affecting the stability of subsequent processing links and failing to meet the precision requirements of modern textile production.

The yarn package monitoring system based on the STC89C52 microcontroller integrates HX711 weighing module, DHT11 temperature and humidity sensor, 3 independent buttons, LCD1602 display, ECB02 Bluetooth module, and sound-light alarm device, realizing automatic monitoring and intelligent early warning of yarn package weight and environment. The core functions of the system include: real-time acquisition of yarn package weight through the HX711 weighing module; detection of current environmental temperature and humidity by means of the DHT11 sensor; triggering sound-light alarm when the monitored weight exceeds the preset maximum value; support for setting the maximum weight value through 3 independent buttons; real-time display of temperature, humidity and weighing values using the LCD1602 display; sending weight values to the mobile phone via the ECB02 Bluetooth module, and sending the early warning message “Weight too high” when the weight reaches the maximum value.

The implementation of this system effectively improves the automation level of yarn package monitoring, reduces errors caused by manual intervention, ensures the accuracy of weight control and real-time performance of environmental monitoring, provides an efficient and reliable solution for textile production, and also offers a reference for the research and development of similar textile monitoring equipment, with high practical application value.

Keywords: STC89C52; Yarn package; Monitoring system; Sensor; Weight control; Bluetooth communication

目录

第 1 章 绪论

1.1 研究的目的及意义

1.2 国内外发展情况

1.3 本文主要研究内容

第2章 设计思路与方案论证

2.1 主要元器件选择

2.1.1 主控芯片选择

2.1.2 称重模块选择

2.1.3 温湿度传感器选择

2.1.4 按键模块选择

2.1.5 显示模块选择

2.1.6 蓝牙模块选择

2.1.7 声光报警模块选择

2.2整体设计方案

第 3 章 硬件设计

3.1 主控电路模块

3.2 称重模块电路

3.3 温湿度传感器电路

3.4 显示模块电路

3.5 蓝牙模块电路

3.6 按键模块电路

3.7 声光报警模块电路

第4章 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 LCD1602显示模块子流程设计

4.4 独立按键子流程设计

4.5 温湿度检测模块子流程设计

4.6 称重模块子流程设计

4.7 蓝牙模块子流程设计

第 5 章 实物测试

5.1 整体实物测试

5.2 称重模块功能测试

5.3 温湿度传感器功能测试

5.4 显示模块功能测试

5.5 蓝牙模块功能测试

5.6 按键模块功能测试

5.7 声光报警模块功能测试

第 6 章 总结与展望

6.1 总结

6.2 展望

致谢

参考文献

附录

附录一:原理图

附录二:PCB

附录三:主程序

购买后可查看具体内容!