设计说明书

总字数:21000+

摘要

在矿井作业环境中,安全保障是生产运营的核心环节,实时监测井下环境参数并及时预警,对保障矿工生命安全、预防事故发生具有重要意义。传统的矿井安全监测方式存在覆盖范围有限、响应滞后、数据反馈不及时等问题,难以满足复杂井下环境的安全管理需求。

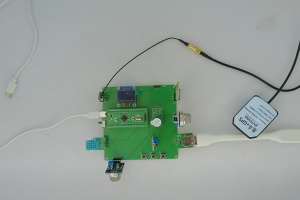

基于 STM32F103C8T6 单片机的矿井安全帽设计,整合了 DHT11 温湿度传感器、MQ-4 甲烷传感器、MQ-135 有害气体传感器、5516 光敏电阻、GPS + 北斗定位模块、3 个独立按键、OLED 显示屏、AIR7804G 模块及声光报警装置、照明设备等,实现了矿井环境的实时监测、自动预警、定位追踪及远程数据传输。系统核心功能包括:通过 DHT11 实时监测温湿度,当数值超出设定范围时触发声光报警;借助 MQ-4 检测甲烷浓度,浓度超标时启动声光报警;利用 MQ-135 监测有害气体浓度,超标时发出声光警示;通过 5516 光敏电阻获取光照值,低于阈值时自动开灯,同时支持按键手动控制照明;通过 GPS + 北斗模块获取实时经纬度,实现人员定位;支持按键设置各参数阈值;通过 OLED 显示屏实时显示监测数据、定位信息及设备状态;利用 AIR7804G 模块将数据传输至手机端,支持手机端设置阈值与远程监控。

该设计的实现,有效提升了矿井安全监测的实时性与智能化水平,为井下作业人员提供了主动安全防护,减少了安全事故的发生风险,同时为矿井安全管理提供了精准的数据支持,具有较高的实际应用价值和推广意义。

关键词:STM32F103C8T6;矿井安全帽;环境监测;定位追踪;声光报警;4G 通信

ABSTRACT

In the mine working environment, safety assurance is the core link of production and operation. Real-time monitoring of underground environmental parameters and timely early warning are of great significance for ensuring the safety of miners’ lives and preventing accidents. Traditional mine safety monitoring methods have problems such as limited coverage, delayed response, and untimely data feedback, which are difficult to meet the safety management needs of complex underground environments.

The design of the mine safety helmet based on the STM32F103C8T6 microcontroller integrates DHT11 temperature and humidity sensors, MQ-4 methane sensors, MQ-135 harmful gas sensors, 5516 photoresistors, GPS+Beidou positioning modules, 3 independent buttons, OLED displays, AIR7804G modules, sound and light alarm devices, lighting equipment, etc., realizing real-time monitoring, automatic early warning, positioning and tracking, and remote data transmission of the mine environment. The core functions of the system include: real-time monitoring of temperature and humidity through DHT11, triggering sound and light alarms when the values exceed the set range; detecting methane concentration with MQ-4, activating sound and light alarms when the concentration exceeds the standard; monitoring harmful gas concentration with MQ-135, issuing sound and light warnings when exceeding the standard; obtaining light values through 5516 photoresistors, automatically turning on the lights when below the threshold, and supporting button manual control of lighting; obtaining real-time latitude and longitude through GPS+Beidou modules to realize personnel positioning; supporting button setting of various parameter thresholds; real-time display of monitoring data, positioning information and equipment status through OLED display; transmitting data to the mobile phone through AIR7804G module, supporting mobile phone setting of thresholds and remote monitoring.

The implementation of this design effectively improves the real-time and intelligent level of mine safety monitoring, provides active safety protection for underground workers, reduces the risk of safety accidents, and provides accurate data support for mine safety management, which has high practical application value and promotion significance.

Keywords: STM32F103C8T6; Mine safety helmet; Environmental monitoring; Positioning and tracking; Sound and light alarm; 4G communication

目录

第 1 章 绪论

1.1 研究的目的及意义

1.2 国内外发展情况

1.3 本文主要研究内容

第2章 设计思路与方案论证

2.1 主要元器件选择

2.1.1 主控芯片选择

2.1.2 温湿度传感器选择

2.1.3 甲烷传感器选择

2.1.4 有害气体传感器选择

2.1.5 光照检测模块选择

2.1.6 定位模块选择

2.1.7 按键模块选择

2.1.8 显示模块选择

2.1.9 4G 模块选择

2.1.10 声光报警模块选择

2.2整体设计方案

第 3 章 硬件设计

3.1 主控电路模块

3.2 温湿度传感器电路

3.3 甲烷传感器电路

3.4 有害气体传感器电路

3.5 光照检测模块电路

3.6 GPS + 北斗定位模块电路

3.7 显示模块电路

3.8 4G 模块电路

3.9 按键模块电路

3.10 声光报警与照明设备驱动电路

第4章 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 OLED显示流程设计

4.5 温湿度检测模块子流程

4.6 4G模块联网子流程设计

4.7 ADC模数转换子流程设计

4.8 GPS模块子流程设计

第 5 章 实物测试

5.1 整体实物测试

5.2 温湿度传感器功能测试

5.3 甲烷传感器功能测试

5.4 有害气体传感器功能测试

5.5 光照检测模块功能测试

5.6 GPS + 北斗定位模块功能测试

5.7 4G 模块功能测试

5.8 按键设置与显示功能测试

5.9 声光报警模块功能测试

第 6 章 总结与展望

6.1 总结

6.2 展望

致谢

参考文献

附录

附录一:原理图

附录二:PCB

附录三:主程序

购买后可查看具体内容!