设计说明书

总字数:18000+

摘要

随着智能家居理念的深入普及,用户对热水器的智能化、安全化与舒适化需求日益提升。传统热水器存在温度控制精度不足、水位监测缺失导致干烧风险、水质酸碱度失衡影响健康等问题,且多依赖本地机械操作,缺乏远程调控能力,难以满足现代家庭的使用需求。因此,研发一款集多参数监测、自动调节、远程控制于一体的智能热水器控制系统具有重要的现实意义。

本设计提出一种基于 STM32F103C8T6 单片机的热水器控制系统。系统核心功能包括:通过防水式 DS18B20 传感器采集水温,当水温低于预设最小值时自动启动加热,达到最大值后停止;借助另一 DS18B20 监测环境温度,低于最小值时触发声光报警模块发出警示;通过双水位触发模块检测水位,低于最低值时自动加水至最高值;利用 PH4502C 传感器测量水质 PH 值,低于最小值时启动加碱装置,高于最大值时启动加酸装置,直至水质恢复中性。系统构建安全逻辑:水温达标且水位充足时启动抽水继电器供水,否则停止;水位过低时锁定加热功能避免干烧。通过 7 个按键实现阈值设置、手动控制(加热、进水、加酸、加碱、抽水)及模式切换;OLED 显示屏实时展示水温、环境温度、水位、PH 值及设备状态;ESP8266 WiFi 模块将数据上传至手机端,支持远程设置阈值、控制器件及切换模式。

该系统的作用在于构建 “监测 – 调节 – 保护 – 交互” 的完整闭环,通过精准的参数控制提升用水舒适度,水位与加热联动机制保障使用安全,水质调节功能维护用水健康,本地与远程双重交互满足多样化操控需求。为家庭提供了高效、安全、智能的热水解决方案,推动热水器向节能化、人性化方向发展。

关键词:单片机;热水器控制;智能调节;远程监控

Abstract

With the deepening popularization of smart home concepts, users’ demand for intelligence, safety, and comfort of water heaters is increasing day by day. Traditional water heaters have problems such as insufficient temperature control accuracy, lack of water level monitoring leading to dry burning risks, water quality acid-base imbalance affecting health, and rely heavily on local mechanical operation, lacking remote control capabilities, making it difficult to meet the needs of modern households. Therefore, developing an intelligent water heater control system that integrates multi parameter monitoring, automatic adjustment, and remote control is of great practical significance.

This design proposes a water heater control system based on STM32F103C8T6 microcontroller. The core functions of the system include: collecting water temperature through a waterproof DS18B20 sensor, automatically starting heating when the water temperature is below the preset minimum value, and stopping when the maximum value is reached; Using another DS18B20 to monitor the ambient temperature, triggering the sound and light alarm module to issue a warning when it falls below the minimum value; Detect the water level through a dual water level triggering module, and automatically add water to the highest value when it is below the lowest value; Use PH4502C sensor to measure the pH value of water quality. When it is below the minimum value, start the alkali adding device. When it is above the maximum value, start the acid adding device until the water quality returns to neutral. System construction safety logic: Start the pumping relay to supply water when the water temperature meets the standard and the water level is sufficient, otherwise stop; Lock the heating function when the water level is too low to avoid dry burning. Threshold setting, manual control (heating, water inlet, acid addition, alkali addition, water extraction), and mode switching can be achieved through 7 buttons; OLED display screen displays real-time water temperature, ambient temperature, water level, pH value, and equipment status; The ESP8266 WiFi module uploads data to the mobile phone and supports remote setting of thresholds, control devices, and switching modes.

The function of this system is to build a complete closed loop of “monitoring regulation protection interaction”, improve water comfort through precise parameter control, ensure safe use through water level and heating linkage mechanism, maintain water health through water quality regulation function, and meet diverse control needs through local and remote dual interaction. Provided efficient, safe, and intelligent hot water solutions for families, promoting the development of water heaters towards energy conservation and humanization.

Keywords:microcontroller; Water heater control; Intelligent regulation; Remote monitoring

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 水温与环境温度检测模块电路设计

3.4 水位检测模块电路设计

3.5 PH 值检测模块电路设计

3.6 继电器执行模块电路设计

3.7 按键模块电路设计

3.8 显示模块电路设计

3.9 声光报警模块电路设计

3.10 WiFi 通信模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 OLED显示子流程设计

4.4 独立按键子流程设计

4.5 温度检测模块子流程设计

4.6 ADC模数转换子流程设计

4.7 WiFi模块子流程设计

5 实物制作与功能测试

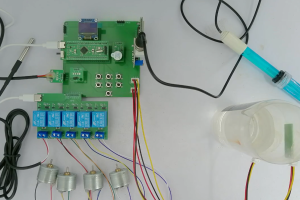

5.1 实物制作

5.2 温度检测与加热控制功能测试

5.3 水位检测与进水控制功能测试

5.4 PH 值检测与酸碱调节功能测试

5.5 供水控制与按键交互功能测试

5.6 WiFi 远程通信功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!