设计说明书

总字数:11000+

随着人们对食品安全和品质的关注度不断提高,酸奶发酵过程的精准控制显得尤为重要。传统酸奶发酵方式难以精确监测与调控发酵环境,导致产品质量不稳定。为此,设计一种基于物联网的酸奶发酵环境监测系统尤为重要。

本设计采用STM32F103C8T6单片机为核心,通过DS18B20传感器实时监测发酵温度,当温度超出设定阈值时自动启动加热或制冷装置,并触发声光报警;利用pH监测模块实时检测发酵环境的酸碱度,一旦pH值异常即发出警报;通过单片机内部时钟模块设置发酵倒计时,时间到时声光报警提醒用户。按键用于手动设置参数和控制加热、制冷、搅拌等功能,OLED显示屏用于实时显示温度、PH等监测数据,WiFi模块则将数据传输至手机端,用户可通过手机远程设置阈值、控制设备,发酵完成时手机端弹窗提醒。

实物测试结果表明,该系统运行稳定,能够实现对酸奶发酵环境的精准监测与调控,有效提高了酸奶产品的质量和稳定性,为酸奶生产企业的智能化升级提供了有力的技术支撑。

关键词:STM32;传感器;WiFi;环境监测

Abstract

With the increasing attention to food safety and quality, precise control of yogurt fermentation process has become particularly important. The traditional yogurt fermentation method is difficult to accurately monitor and regulate the fermentation environment, resulting in unstable product quality. Therefore, it is particularly important to design an IoT based yogurt fermentation environment monitoring system.

This design uses STM32F103C8T6 microcontroller as the core, and monitors the fermentation temperature in real time through DS18B20 sensor. When the temperature exceeds the set threshold, the heating or cooling device will automatically start and trigger an audible and visual alarm; Utilize pH monitoring module to detect the acidity and alkalinity of the fermentation environment in real-time, and issue an alarm once the pH value is abnormal; Set the fermentation countdown through the internal clock module of the microcontroller, and sound and light alarms to remind users when the time is up. The buttons are used to manually set parameters and control heating, cooling, stirring, and other functions. The OLED display screen is used to display real-time monitoring data such as temperature and pH. The WiFi module transmits the data to the mobile phone, and users can remotely set thresholds and control devices through the phone. When fermentation is completed, a pop-up reminder will appear on the mobile phone.

The physical test results show that the system runs stably and can achieve precise monitoring and regulation of the yogurt fermentation environment, effectively improving the quality and stability of yogurt products and providing strong technical support for the intelligent upgrading of yogurt production enterprises.

Keywords: STM32; Sensors; WiFi; environmental monitoring

目 录

一、绪论

(一)研究背景与意义

(二)国内外研究现状

1.国内研究现状

2.国外研究现状

(三)研究内容

二、系统总体设计

(一)系统方案设计

(二)主要器件选择

1.主控芯片选择

2.温度监测模块选择

3.WiFi模块选择

三、系统硬件设计

(一)主控模块电路设计

1.STM32F103C8T6单片机简介

2.单片机最小系统设计

(二)温度检测模块电路设计

(三)PH检测模块电路设计

(四)按键模块模块电路设计

(五)显示模块模块电路设计

(六)声光报警模块电路设计

(七)继电器控制模块电路设计

(八)WiFi模块电路设计

四、系统程序设计

(一)编程软件介绍

(二)系统主流程设计

(三)独立按键模块子流程

(四)温度检测模块子流程

(五)WiFi模块子流程设计

五、调试与功能测试

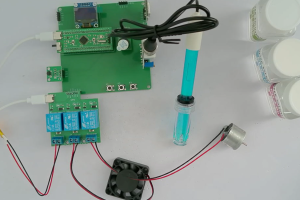

(一)整体焊接实物

(二)发酵温度测控模块测试

(三)发酵PH测控实物测试

(四)倒计时结束实物测试

(五)WiFi模块实物测试

结 论

参考文献

致 谢

购买后可查看具体内容!