设计说明书

总字数:17000+

摘要

在矿井开采作业中,井下环境的安全监测是保障生产安全与人员生命健康的关键环节。传统的人工巡检方式不仅依赖经验判断、响应迟缓,还存在监测范围有限、数据记录不及时等问题,难以适应现代化矿井安全管理的需求。

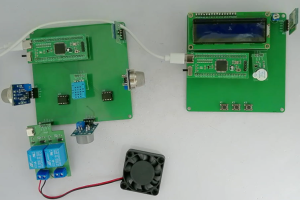

基于 STC89C52 单片机的井下安全监测系统,整合了 DHT11 温湿度传感器、MQ-5 可燃气体传感器、MQ-7 一氧化碳传感器、MQ-135 有害混合气体传感器、Zigbee 无线传输模块、继电器、上位机显示屏及独立按键等设备,实现了井下环境的实时监测与自动预警。系统核心功能包括:下位机通过 DHT11 实时监测井下温湿度,当温度超过设定最大值时,自动启动通风装置;通过 MQ-5 监测可燃气体浓度,超过阈值时触发继电器模拟断电操作;借助 MQ-7 检测一氧化碳浓度,超标时联动继电器实现断电;通过 MQ-135 监测有害混合气体浓度,超出限值后自动执行断电保护;所有监测数据通过 Zigbee 模块传输至上位机。上位机通过 Zigbee 接收数据并在显示屏实时展示,同时支持通过 3 个独立按键设置各项参数阈值,当监测值偏离阈值范围时,立即启动声光报警。

该系统的应用,有效提升了井下安全监测的自动化与实时性,减少了人工巡检的安全风险,确保了异常情况的快速响应,为矿井安全生产提供了可靠的技术支撑,同时为同类井下监测设备的研发提供了实践参考,具有重要的实用价值。

关键词:STC89C52;井下安全;监测系统;传感器;Zigbee 传输;自动预警

ABSTRACT

In mine mining operations, safety monitoring of the underground environment is a key link in ensuring production safety and personnel health. Traditional manual inspection methods not only rely on empirical judgment with slow responses but also have problems such as limited monitoring range and untimely data recording, making them difficult to meet the needs of modern mine safety management.

The underground safety monitoring system based on the STC89C52 microcontroller integrates DHT11 temperature and humidity sensors, MQ-5 combustible gas sensors, MQ-7 carbon monoxide sensors, MQ-135 harmful mixed gas sensors, Zigbee wireless transmission modules, relays, host computer displays, and independent buttons, realizing real-time monitoring and automatic early warning of the underground environment. The core functions of the system include: the lower computer monitors underground temperature and humidity in real-time through DHT11, and automatically starts the ventilation device when the temperature exceeds the set maximum value; monitors the concentration of combustible gas through MQ-5, and triggers the relay to simulate power-off operation when it exceeds the threshold; detects the concentration of carbon monoxide with MQ-7, and links the relay to achieve power-off when exceeding the standard; monitors the concentration of harmful mixed gases through MQ-135, and automatically implements power-off protection after exceeding the limit; all monitoring data is transmitted to the upper computer through the Zigbee module. The upper computer receives data through Zigbee and displays it in real-time on the display. It also supports setting various parameter thresholds through 3 independent buttons. When the monitored value deviates from the threshold range, it immediately activates an audible and visual alarm.

The application of this system effectively improves the automation and real-time performance of underground safety monitoring, reduces the safety risks of manual inspection, ensures the rapid response to abnormal situations, provides reliable technical support for safe mine production, and also offers practical reference for the research and development of similar underground monitoring equipment, with important practical value.

Keywords: STC89C52; Underground safety; Monitoring system; Sensor; Zigbee transmission; Automatic early warning

目录

第 1 章 绪论

1.1 研究的目的及意义

1.2 国内外发展情况

1.3 本文主要研究内容

第2章 设计思路与方案论证

2.1 主要元器件选择

2.1.1 主控芯片选择

2.1.2 温湿度传感器选择

2.1.3 可燃气体传感器选择

2.1.4 一氧化碳传感器选择

2.1.5 有害混合气体传感器选择

2.1.6 无线传输模块选择

2.1.7 显示模块选择

2.1.8 按键模块选择

2.2整体设计方案

第 3 章 硬件设计

3.1 主控电路模块

3.2 温湿度传感器电路

3.3 可燃气体传感器电路

3.4 一氧化碳传感器电路

3.5 有害混合气体传感器电路

3.6 Zigbee 无线传输模块电路

3.7 显示模块电路

3.8 按键模块电路

3.9 执行模块电路

第4章 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 从机系统主流程设计

4.4 独立按键

4.5 OLED显示流程设计

4.6 ADC模数转换子流程设计

4.7 温湿度检测模块子流程设计

4.8 zigbee模块子流程设计

第 5 章 实物测试

5.1 整体实物测试

5.2 温湿度传感器功能测试

5.3 可燃气体传感器功能测试

5.4 一氧化碳传感器功能测试

5.5 有害混合气体传感器功能测试

5.6 Zigbee 无线传输模块功能测试

5.7 按键设置与显示功能测试

第 6 章 总结与展望

6.1 总结

6.2 展望

致谢

参考文献

附录

附录一:原理图

附录二:PCB

附录三:主程序

购买后可查看具体内容!