设计说明书

总字数:17000+

摘要

在煤矿井下生产作业中,煤粉浓度过高易引发粉尘爆炸、危害作业人员呼吸系统等安全健康问题,实时精准监测煤粉浓度并及时采取降尘措施,是保障井下生产安全与人员健康的关键环节。当前传统煤粉检测方式存在响应滞后、人工干预多、降尘不及时等问题,难以满足井下连续作业的安全监测需求,因此研发一款自动化、便捷化的井下煤粉检测仪具有重要现实意义。

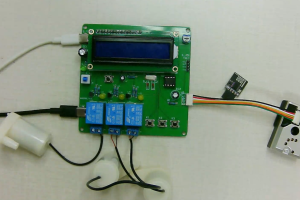

本设计提出一种基于 STC89C52 单片机的井下煤粉检测仪。在煤粉浓度检测模块,通过 GP2Y1014AU 粉尘传感器实时采集井下煤粉浓度信号,传感器将浓度信号转换为电信号传输至单片机,实现对煤粉浓度的持续监测。在阈值设置模块,用户可通过按键自由设置煤粉浓度最大值,设置参数实时存储,便于根据不同井下作业场景调整安全阈值,提升检测灵活性。在异常报警与自动降尘模块,当单片机判断监测到的煤粉浓度大于预设最大值时,立即触发声光报警模块发出警示信号,同时控制继电器吸合,启动雾化片进行降尘作业,降低煤粉浓度至安全范围。在数据显示模块,通过 LCD1602 液晶显示屏清晰展示预设的煤粉浓度最大值与实时监测的煤粉浓度值,方便作业人员直观掌握浓度变化情况。在远程控制模块,借助 ECBO2 蓝牙模块实现手机或其他终端与检测仪的无线通信,用户可通过蓝牙远程控制继电器通断,进而控制雾化片启动或停止降尘,提升操作便捷性。

该井下煤粉检测仪为煤矿井下煤粉浓度监测与降尘控制提供了自动化解决方案,通过实时监测、及时报警与自动降尘,有效降低煤粉浓度超标的安全风险,同时远程控制与直观显示功能提升了操作便利性,为保障井下生产安全、保护作业人员健康发挥重要作用。

关键词:单片机;井下煤粉检测仪;浓度检测;声光报警;蓝牙控制

Design and Implementation of Underground Coal Powder Detection Instrument Based on Single Chip Microcomputer

Abstract

In the underground production of coal mines, too high concentration of pulverized coal is likely to cause dust explosion, endanger the respiratory system of operators and other safety and health problems. Real time accurate monitoring of pulverized coal concentration and timely taking dust reduction measures are the key links to ensure the safety of underground production and personnel health. The current traditional coal powder detection method has problems such as delayed response, excessive manual intervention, and untimely dust reduction, which are difficult to meet the safety monitoring needs of continuous underground operations. Therefore, developing an automated and convenient underground coal powder detector has important practical significance.

This design proposes an underground coal powder detector based on STC89C52 microcontroller. In the coal powder concentration detection module, the GP2Y1014AU dust sensor collects real-time coal powder concentration signals underground. The sensor converts the concentration signal into an electrical signal and transmits it to the microcontroller to achieve continuous monitoring of coal powder concentration. In the threshold setting module, users can freely set the maximum coal powder concentration value through buttons, and set parameters for real-time storage, making it easy to adjust the safety threshold according to different underground operation scenarios and improve detection flexibility. In the abnormal alarm and automatic dust reduction module, when the microcontroller determines that the monitored coal powder concentration is greater than the preset maximum value, it immediately triggers the sound and light alarm module to issue a warning signal, and controls the relay to close, starting the atomization plate for dust reduction operation, and reducing the coal powder concentration to a safe range. In the data display module, the LCD1602 LCD screen clearly displays the preset maximum coal powder concentration value and the real-time monitored coal powder concentration value, making it convenient for operators to intuitively grasp the concentration changes. In the remote control module, wireless communication between mobile phones or other terminals and the detector is achieved through the ECBO2 Bluetooth module. Users can remotely control the relay on and off through Bluetooth, thereby controlling the start or stop of dust reduction on the atomizing plate, improving operational convenience.

The underground coal powder detector provides an automated solution for monitoring coal powder concentration and dust reduction control in coal mines. Through real-time monitoring, timely alarm and automatic dust reduction, it effectively reduces the safety risk of coal powder concentration exceeding the standard. At the same time, remote control and intuitive display functions improve operational convenience, playing an important role in ensuring underground production safety and protecting the health of workers.

Keywords: microcontroller; Underground coal powder detector; Concentration detection; Sound and light alarm; Bluetooth control

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 煤粉浓度检测模块电路设计

3.4 显示模块电路设计

3.5 按键模块电路设计

3.6 声光报警模块电路设计

3.7 降尘执行模块电路设计

3.8 蓝牙模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 GP2Y10模块子流通

4.5 A/D模数转换子流程

4.6 LCD1602液晶显示子流程

4.7 蓝牙模块子流程

5 实物制作与功能测试

5.1 实物制作

5.2 煤粉浓度检测功能测试

5.3 阈值设置与显示功能测试

5.4 声光报警与自动降尘功能测试

5.5 蓝牙远程控制功能测试

5.6 手动模式与自动模式切换测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!