设计说明书

总字数:19000+

摘要

随着城市化进程加快,地下管网(燃气、排水)覆盖范围持续扩大,井盖作为管网重要组成部分,其安全管理问题日益凸显。传统井盖缺乏实时监测手段,易出现井盖移位(导致行人坠落)、井下甲烷气体泄漏(引发爆炸风险)、水位过高(造成管网堵塞)等隐患,且故障发现依赖人工巡检,响应滞后,难以满足城市安全管理的实时性、精准性需求。因此,研发一套能实时监测井盖状态、及时预警风险的智能监测系统,对保障城市公共安全、提升管网管理效率具有重要现实意义。

本设计提出一种基于 STM32F103C8T6 单片机的智能井盖监测系统。在气体监测与通风模块,通过 MQ-4 甲烷传感器实时采集井盖下甲烷浓度,当浓度超过按键设置的最大值时,STM32F103C8T6 驱动继电器启动通风设备,降低爆炸风险;在井盖状态监测模块,借助 MPU6050 六轴传感器检测井盖的加速度与角度变化,判断是否发生移位或倾斜,及时发现井盖丢失、损坏隐患;在水位监测模块,通过 HC-SR04 超声波模块测量井盖下方水位高度,为管网排水调度提供数据支撑;在参数设置模块,通过独立按键可灵活调整甲烷浓度最大值阈值,适配不同区域(如燃气井、污水井)的监测需求;在数据显示模块,通过 OLED 显示屏实时展示甲烷浓度、水位高度、井盖状态及预设阈值,便于巡检人员现场查看;在报警模块,当监测到甲烷浓度超标、水位过高或井盖移位时,系统立即触发声光报警,提醒周边人员远离危险区域;在远程通信模块,通过 NB-IoT 模块将甲烷浓度、水位、井盖状态等参数实时传输至手机端,实现管理人员远程实时监控,无需现场巡检即可掌握井盖动态。

该智能井盖监测系统的核心价值在于,构建了 “实时监测 – 自动预警 – 远程管控” 的一体化管理模式。通过多维度传感器与单片机的协同,实现井盖风险的精准识别与快速响应,大幅降低人工巡检成本,缩短故障处置时间;同时,远程数据传输功能为城市管网智慧管理提供数据支撑,助力提升城市公共安全水平与基础设施管理效率。

关键词:单片机;智能井盖;甲烷检测;井盖移位监测;水位监测;NB-IoT 远程传输

Design of Intelligent Manhole Cover Monitoring System Based on Single Chip Microcomputer

Abstract

With the acceleration of urbanization, the coverage of underground pipelines (gas, drainage) continues to expand. As an important component of the pipeline network, the safety management of manhole covers is becoming increasingly prominent. Traditional manhole covers lack real-time monitoring methods, which can lead to hidden dangers such as cover displacement (causing pedestrians to fall), methane gas leakage under the well (causing explosion risks), and high water levels (causing pipe network blockages). Moreover, fault detection relies on manual inspection, with delayed response, making it difficult to meet the real-time and accurate requirements of urban safety management. Therefore, developing an intelligent monitoring system that can monitor the status of manhole covers in real time and warn of risks in a timely manner is of great practical significance for ensuring urban public safety and improving pipeline management efficiency.

This design proposes an intelligent manhole cover monitoring system based on STM32F103C8T6 microcontroller. In the gas monitoring and ventilation module, the methane concentration under the manhole cover is collected in real time through the MQ-4 methane sensor. When the concentration exceeds the maximum value set by the button, the STM32F103C8T6 drives the relay to activate the ventilation equipment, reducing the risk of explosion; In the manhole cover status monitoring module, the MPU6050 six axis sensor is used to detect the acceleration and angle changes of the manhole cover, determine whether there is displacement or tilt, and timely detect the hidden dangers of lost or damaged manhole covers; In the water level monitoring module, the HC-SR04 ultrasonic module is used to measure the water level height below the manhole cover, providing data support for pipeline drainage scheduling; In the parameter setting module, the maximum threshold of methane concentration can be flexibly adjusted through independent buttons to adapt to the monitoring needs of different areas (such as gas wells and sewage wells); In the data display module, the methane concentration, water level height, manhole cover status, and preset threshold are displayed in real time through an OLED screen, making it easy for inspection personnel to view on site; In the alarm module, when the methane concentration exceeds the standard, the water level is too high, or the manhole cover is displaced, the system immediately triggers an audible and visual alarm to remind surrounding personnel to stay away from the dangerous area; In the remote communication module, parameters such as methane concentration, water level, and manhole cover status are transmitted in real-time to the mobile phone through the NB IoT module, enabling remote real-time monitoring by management personnel without the need for on-site inspections to grasp the dynamics of the manhole cover.

The core value of this intelligent manhole cover monitoring system lies in the construction of an integrated management mode of “real-time monitoring automatic warning remote control”. Through the collaboration of multi-dimensional sensors and microcontrollers, precise identification and rapid response of manhole cover risks can be achieved, significantly reducing manual inspection costs and shortening fault handling time; At the same time, the remote data transmission function provides data support for the intelligent management of urban pipeline networks, helping to improve the level of urban public safety and the efficiency of infrastructure management.

Keywords: microcontroller; Intelligent manhole cover; Methane detection; Monitoring of manhole cover displacement; Water level monitoring; NB IoT remote transmission

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 甲烷监测与通风模块电路设计

3.4 井盖移位监测模块电路设计

3.5 水位监测模块电路设计

3.6 参数设置模块电路设计

3.7 显示模块电路设计

3.8 声光报警模块电路设计

3.9 远程通信模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 甲烷检测模块子流程设计

4.4 OLED显示屏子流程设计

4.5 独立按键子流程设计

4.6 MPU6050模块子流程设计

4.7 超声波检测模块子流程设计

4.8 NB-IOT模块联网子流程设计

5 实物制作与功能测试

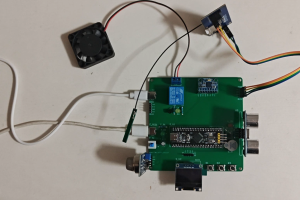

5.1 实物制作

5.2 甲烷监测与通风功能测试

5.3 井盖移位监测功能测试

5.4 水位监测功能测试

5.5 参数设置功能测试

5.6 远程通信功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!