设计说明书

总字数:19000+

摘要

随着工业生产与民用供暖对锅炉依赖度的提升,锅炉运行过程中的水温、水位、压力等参数的精准控制,成为保障设备安全、提升能源利用效率的关键环节。传统锅炉管理多依赖人工巡检,易出现参数监测不及时、操作滞后等问题,不仅可能导致能源浪费,还可能因压力超标、水位过低引发设备故障甚至安全事故。因此,研发一种能自动监测、智能调控且具备安全预警功能的锅炉管理系统,具有重要的实用价值与安全意义。

本设计提出了一种基于 STM32F103C8T6 单片机的智能锅炉管理系统。系统主要功能包括:通过防水式 DS18B20 传感器采集锅炉水温,当水温低于设置最小值时,驱动继电器启动加热设备,直至水温升至设定最大值;借助两个 YW-01D 水位触发模块检测水位,当水位低于最低值时,启动加水继电器补水,直至水位达到最高值;通过 FSR402 压力传感器实时监测锅炉压力,若压力超过设置最大值,立即触发声光报警并切断设备电源;仅当水温高于设置最小值且水位高于最低值时,启动供水继电器正常供水,否则停止供水,同时水位低时禁止启动加热功能;支持通过按键手动设置各参数阈值及控制加热、加水操作;通过 OLED 显示屏清晰展示水温、水位、压力等实时数据及设定阈值;搭载 ESP8266-12F WIFI 模块,可将测量数据实时发送至手机端,用户还能通过手机远程设置阈值、控制加热与加水操作。

该智能锅炉管理系统的作用在于,为锅炉运行提供全流程智能化管理方案。通过多参数自动监测与联动调控,既能保障锅炉安全稳定运行,避免压力超标、干烧等安全隐患,又能减少人工干预,提升能源利用效率;远程控制与数据可视化功能,进一步增强了管理的便捷性与及时性,为工业生产与民用场景的锅炉管理提供可靠保障。

关键词:智能锅炉管理系统;STM32F103C8T6;多参数监测;WIFI 远程控制

Intelligent Boiler Management System Based on Single Chip Microcomputer

Abstract

With the increasing dependence of industrial production and civilian heating on boilers, precise control of parameters such as water temperature, water level, and pressure during boiler operation has become a key link in ensuring equipment safety and improving energy utilization efficiency. Traditional boiler management relies heavily on manual inspections, which can lead to problems such as untimely parameter monitoring and delayed operation. This not only results in energy waste, but also may cause equipment failures or even safety accidents due to excessive pressure or low water levels. Therefore, developing a boiler management system that can automatically monitor, intelligently regulate, and has safety warning functions has important practical value and safety significance.

This design proposes an intelligent boiler management system based on STM32F103C8T6 microcontroller. The main functions of the system include: collecting boiler water temperature through a waterproof DS18B20 sensor. When the water temperature is below the set minimum value, the relay is driven to start the heating equipment until the water temperature reaches the set maximum value; Using two YW-01D water level triggering modules to detect the water level, when the water level is below the minimum value, the water addition relay is activated to replenish water until the water level reaches the highest value; Real time monitoring of boiler pressure through FSR402 pressure sensor. If the pressure exceeds the set maximum value, an audible and visual alarm will be triggered immediately and the equipment power will be cut off; Only when the water temperature is higher than the set minimum value and the water level is higher than the minimum value, the water supply relay is activated to supply water normally. Otherwise, the water supply is stopped, and the heating function is prohibited from being activated when the water level is low; Support manual setting of parameter thresholds and control of heating and water addition operations through buttons; Clear display of real-time data such as water temperature, water level, pressure, and set thresholds through OLED screens; Equipped with ESP8266-12F WIFI module, it can send real-time measurement data to the mobile phone, and users can also remotely set thresholds, control heating and water addition operations through their mobile phone.

The function of this intelligent boiler management system is to provide a full process intelligent management solution for boiler operation. Through multi parameter automatic monitoring and linkage regulation, it can not only ensure the safe and stable operation of the boiler, avoid safety hazards such as pressure exceeding standards and dry burning, but also reduce manual intervention and improve energy utilization efficiency; The remote control and data visualization functions further enhance the convenience and timeliness of management, providing reliable support for boiler management in industrial production and civilian scenarios.

Keywords: intelligent boiler management system; STM32F103C8T6; Multi parameter monitoring; WIFI remote control

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 水温检测模块电路设计

3.4 水位检测模块电路设计

3.5 压力检测模块电路设计

3.6 继电器控制模块电路设计

3.7 声光报警模块电路设计

3.8 显示模块电路设计

3.9 按键模块电路设计

3.10 WIFI 通信模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 温度检测模块子流程设计

4.5 水位检测模块子流程设计

4.6 OLED显示流程设计

4.7 WiFi模块子流程设计

5 实物制作与功能测试

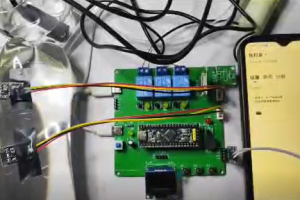

5.1 实物制作

5.2 水温与水位检测及联动控制功能测试

5.3 压力检测与声光报警功能测试

5.4 供水联动与手动控制功能测试

5.5 OLED 显示与按键阈值设置功能测试

5.6 WIFI 远程通信与控制功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!