设计说明书

总字数:17000+

摘要

在咖啡生产中,发酵环节的参数把控直接影响咖啡风味,传统发酵依赖人工调控水量、温度与 PH 值,易出现配比偏差大、参数不稳定等问题,导致咖啡品质参差不齐,难以满足规模化生产对标准化的需求,因此研发自动化咖啡发酵控制系统具有重要现实意义。

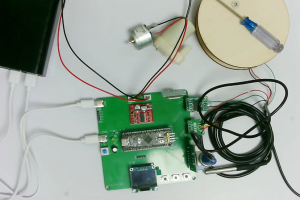

本设计提出基于 STM32F103C8T6 单片机的咖啡自动发酵机器控制系统。系统核心功能包括:通过 HX711 检测咖啡豆重量,依预设比例由 MX1508 驱动水泵精准加水;借助 DS18B20 与 PH4502C 分别采集发酵温度与 PH 值,按参数波动调控搅拌器转速(波动 ±1 不转、±2 低速、±2 以上高速);支持按键设置水量比例、温度及 PH 目标值,OLED 实时显示重量、温度与 PH;通过 ESP8266-12F WiFi 将数据传至手机端,实现远程参数查看与设置。

该系统为咖啡生产提供精准自动化解决方案,减少人工干预成本,保障发酵参数稳定,提升咖啡品质一致性,助力咖啡生产从经验化向标准化转型,为企业提升产品竞争力提供技术支持。

关键词:STM32F103C8T6;咖啡发酵;HX711重;PH调控;WiFi

Control System for STM32 Coffee Automatic Fermentation Machine

Abstract

In coffee production, the control of fermentation parameters directly affects the flavor of coffee. Traditional fermentation relies on manual regulation of water volume, temperature, and pH value, which can lead to large ratio deviations and unstable parameters, resulting in uneven coffee quality and difficulty in meeting the standardization requirements of large-scale production. Therefore, the development of an automated coffee fermentation control system is of great practical significance.

This design proposes a coffee automatic fermentation machine control system based on STM32F103C8T6 microcontroller. The core functions of the system include: detecting the weight of coffee beans through HX711, and accurately adding water to the water pump driven by MX1508 according to the preset ratio; Using DS18B20 and PH4502C to collect fermentation temperature and pH value respectively, adjust the agitator speed according to parameter fluctuations (fluctuation ± 1 no rotation, ± 2 low speed, ± 2 or above high speed); Support button settings for water ratio, temperature, and pH target values, with OLED real-time display of weight, temperature, and pH. Data can be transmitted to the mobile phone via ESP8266-12F WiFi for remote parameter viewing and setting.

This system provides precise automation solutions for coffee production, reducing manual intervention costs, ensuring stable fermentation parameters, improving coffee quality consistency, helping coffee production transition from experience based to standardized, and providing technical support for enterprises to enhance product competitiveness.

Keywords:STM32F103C8T6; Coffee fermentation; HX711 heavy; PH regulation; WiFi

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 参数检测模块电路设计

3.4 电机驱动模块电路设计

3.5 交互与通信模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 称重模块HX711模块子流程

4.5 温度检测模块子流程

4.6 PH检测模块子流程设计

4.7 OLED显示流程设计

4.8 WiFi模块子流程设计

4.9 直流电机-MX1508驱动模块子流程

5 实物制作与功能测试

5.1 实物制作

5.2 参数检测功能测试

5.3 自动加水功能测试

5.4 智能搅拌功能测试

5.5 交互与通信功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!