设计说明书

总字数:19000+

随着传统酿造行业的智能化升级,酒酿过程中温湿度、气压、酒精浓度等参数的精准管控愈发重要。酒酿品质高度依赖环境与物料状态的稳定性,温度异常易导致发酵失败,气压过高可能引发容器爆裂,酒精泄露存在安全隐患,而传统人工监测方式效率低且难以实现实时预警。因此,研发一种智能化的辅助酒酿设备十分必要。

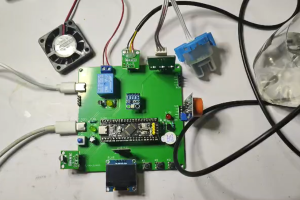

本设计提出一种基于 STM32F103C8T6 单片机的辅助酒酿设备。系统主要功能包括:通过 DS18B20(含防水型)分别检测环境及酒精液体内部温度,借助 BMP180 检测大气压,通过 MQ-3 检测酒精浓度,利用 TSW-30 检测液体浑浊度;用户通过按键设置各参数阈值,OLED 显示屏实时显示 “辅助酒酿设备” 标识及各类检测数据;当任一参数超出阈值时,触发声光报警并通过蓝牙发送对应异常信息,气压异常时自动打开继电器泄压;同时支持蓝牙将实时数据上传至手机端,手机可远程控制继电器开关。

该辅助酒酿设备的作用在于,为酒酿过程提供多维度、智能化的监测与管控工具。通过实时监测、自动预警与远程控制,有效降低人工成本,规避生产风险,保障酒酿品质与生产安全,推动传统酿造行业的标准化发展。

关键词:STM32 单片机;辅助酒酿设备;多参数监测;蓝牙通信;智能管控

Design and Implementation of Auxiliary Wine Brewing Equipment Based on STM32 Single-Chip Microcomputer

Abstract

With the intelligent upgrading of the traditional brewing industry, the precise control of parameters such as temperature, humidity, air pressure, and alcohol concentration during wine brewing has become increasingly important. The quality of wine brewing is highly dependent on the stability of the environment and material status: abnormal temperature can easily lead to fermentation failure, excessive air pressure may cause container explosion, and alcohol leakage poses safety hazards. However, the traditional manual monitoring method is inefficient and difficult to achieve real-time early warning. Therefore, it is very necessary to develop an intelligent auxiliary wine brewing equipment.

This design proposes an auxiliary wine brewing equipment based on the STM32F103C8T6 single-chip microcomputer. The main functions of the system include: detecting the ambient temperature and the internal temperature of alcohol liquid respectively through DS18B20 (including waterproof type), monitoring atmospheric pressure with BMP180, detecting alcohol concentration via MQ-3, and measuring the turbidity of liquid with TSW-30; users set thresholds of various parameters through buttons, and the OLED display screen real-time shows the logo “Auxiliary Wine Brewing Equipment” and various detection data; when any parameter exceeds the threshold, it triggers sound and light alarm and sends corresponding abnormal information via Bluetooth, and automatically turns on the relay to release pressure when air pressure is abnormal; meanwhile, it supports uploading real-time data to the mobile phone via Bluetooth, and the mobile phone can remotely control the relay switch.

The function of this auxiliary wine brewing equipment is to provide a multi-dimensional and intelligent monitoring and control tool for the wine brewing process. Through real-time monitoring, automatic early warning and remote control, it effectively reduces labor costs, avoids production risks, ensures the quality of wine brewing and production safety, and promotes the standardized development of the traditional brewing industry.

Key words: STM32 Single-Chip Microcomputer; Auxiliary Wine Brewing Equipment; Multi-parameter Monitoring; Bluetooth Communication; Intelligent Control

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1 系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 多参数检测模块电路设计

3.4 交互与通信模块电路设计

3.5 报警与执行模块电路设计

3.6 电源模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 温度检测模块子流程设计

4.4 大气压检测模块子流程设计

4.5 酒精检测模块子流程设计

4.6 浑浊度检测模块子流程设计

4.7 独立按键子流程设计

4.8 OLED显示屏子流程设计

4.9 蓝牙模块子流程设计

4.10 声光报警模块子流程设计

5 实物制作与功能测试

5.1 实物制作

5.2 多参数检测与显示功能测试

5.3 阈值设置与蓝牙通信功能测试

5.4 声光报警功能测试

5.5 继电器自动控制功能测试

5.6 综合场景功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!