设计说明书

总字数:22000+

摘要

随着工业自动化水平的提升和生产效率要求的提高,传送带的智能化控制、精准监测及安全防护成为工业生产领域关注的重要环节。传统传送带多依赖人工操作,存在运行不够灵活、监测功能单一、安全防护不足等问题,可能导致生产效率低下、物体脱落损坏或引发安全事故。因此,研发一种集自动运行、精准监测、多方式控制于一体的智能传送带十分必要。

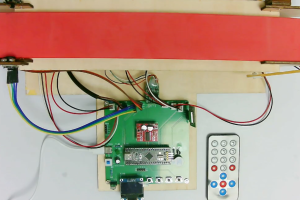

本设计提出了一种基于 STM32F103C8T6 单片机的智能传送带。系统主要功能包括:通过 HX711 模块测量传送带上物体重量,有物体时传送带自动低速运行,无物体时自动停止,且支持通过按键或遥控器进行调速;可通过按键控制传送带向左、向右转动,并借助 MX1508 驱动直流电机实现停止、低速、中速、高速四个挡位的调速,同时设有紧急停止键;通过 VS1838 红外遥控器可远程控制传送带向左、向右转动及四个挡位的调速,同样配备紧急停止键;利用两对红外对射管监测传送带两侧物体是否超出范围,物体超出时蜂鸣器报警以防止脱落;通过 OLED 显示屏显示物体计数、物体温度、物体重量、传送带转动方向(向左、向右)及速度挡位(停止、低速、中速、高速);借助 KY-003 霍尔传感器检测物体触发信号,触发时传送带停止运行;通过 E18-D80NK 光电传感器对传送物体进行计数;利用 MLX90614 红外测温模块测量物体温度;此外,通过 ESP8266-12F WIFI 模块可将相关数据发送至手机端,且手机端能对传送带进行控制。

该智能传送带的作用在于,为工业生产提供了一种高效、安全、便捷的物料传输工具。通过自动运行控制、多维度监测、多方式远程操控及及时报警功能,能够有效提升生产效率,减少物体损坏风险,保障生产安全,为工业自动化生产流程的优化提供有力支持。

关键词:智能传送带;重量测量;多方式控制;物体监测;数据传输

Abstract

With the improvement of industrial automation level and the increasing demand for production efficiency, intelligent control, precise monitoring, and safety protection of conveyor belts have become important aspects of industrial production. Traditional conveyor belts rely heavily on manual operation and suffer from issues such as inflexible operation, single monitoring function, and insufficient safety protection, which may lead to low production efficiency, object detachment and damage, or safety accidents. Therefore, it is necessary to develop an intelligent conveyor belt that integrates automatic operation, precise monitoring, and multi-mode control.

This design proposes an intelligent conveyor belt based on STM32F103C8T6 microcontroller. The main functions of the system include: measuring the weight of objects on the conveyor belt through the HX711 module, automatically running at low speed when there are objects, automatically stopping when there are no objects, and supporting speed adjustment through buttons or remote control; The conveyor belt can be controlled to rotate left and right through buttons, and the MX1508 is used to drive the DC motor to achieve speed regulation in four gears: stop, low speed, medium speed, and high speed. At the same time, an emergency stop button is provided; The VS1838 infrared remote control can be used to remotely control the left and right rotation of the conveyor belt and adjust the speed of four gears, also equipped with an emergency stop button; Use two pairs of infrared tubes to monitor whether objects on both sides of the conveyor belt exceed the range. When an object exceeds the range, the buzzer will sound an alarm to prevent it from falling off; Display object count, object temperature, object weight, conveyor belt rotation direction (left, right) and speed gear (stop, low speed, medium speed, high speed) through OLED display screen; Using KY-003 Hall sensor to detect object trigger signal, the conveyor belt stops running when triggered; Count the transported objects using E18-D80NK photoelectric sensors; Measure the temperature of an object using the MLX90614 infrared temperature measurement module; In addition, relevant data can be sent to the mobile phone through the ESP8266-12F WIFI module, and the mobile phone can control the conveyor belt.

The function of this intelligent conveyor belt is to provide an efficient, safe, and convenient material transfer tool for industrial production. Through automatic operation control, multi-dimensional monitoring, multi-mode remote control, and timely alarm functions, it can effectively improve production efficiency, reduce the risk of object damage, ensure production safety, and provide strong support for the optimization of industrial automation production processes.

Keywords:intelligent conveyor belt; Weight measurement; Multi mode control; Object monitoring; data transmission

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 重量检测模块电路设计

3.4 电机驱动与控制模块电路设计

3.5 安全监测模块电路设计

3.6 数据采集模块电路设计

3.7 显示模块电路设计

3.8 无线通信模块电路设计

4 系统程序设计

4.1 Keil5编程软件介绍

4.2 主程序设计

4.3 独立按键

4.4 称重模块HX711模块子流程

4.5 直流电机-MX1508驱动模块子流程

4.6 OLED显示流程设计

4.7 WiFi模块子流程设计

4.8 霍尔模块子流程设计

4.9 分离式红外开关模块子流程设计

4.10 红外接收模块子流程设计

4.11 红外测温模块子流程设计

4.12 光电检测模块子流程设计

5 实物制作与功能测试

5.1 实物制作

5.2 重量检测与自动运行功能测试

5.3 手动与遥控控制功能测试

5.4 安全监测与报警功能测试

5.5 数据采集与显示功能测试

5.6 WIFI 远程通信与控制功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!