设计说明书

总字数:22000+

摘要

随着煤矿开采规模的不断扩大和安全生产意识的日益增强,煤矿井下环境参数的实时监测与预警成为保障矿工生命安全和生产稳定的关键环节。煤矿井下瓦斯浓度超标、温湿度异常、粉尘浓度过高以及风速风向不适等情况,若不能及时监测和处理,可能引发爆炸、中毒、粉尘危害等严重安全事故,甚至造成重大人员伤亡和财产损失。因此,研发一种能实时、准确监测煤矿环境多参数并具备预警功能的系统十分必要。

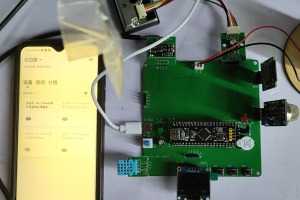

本设计提出了一种基于 STM32F103C8T6 单片机的煤矿环境监测及预警系统。系统主要功能包括:通过 MQ-4 传感器实时监测井下瓦斯浓度,保障避免瓦斯爆炸风险;借助 DHT11 传感器检测当前环境的温湿度,防止温湿度异常影响设备运行和矿工健康;通过 GP2Y1014AU 传感器监测粉尘浓度,减少粉尘对矿工呼吸系统的危害;利用 “小型直流有刷电机 + 三杯式旋转风杯” 组成的风速模块监测当前环境的风速,确保井下通风状况良好;通过格雷码型风向传感器监测当前环境的风向,辅助判断井下气流走向;用户可通过按键设置各环境参数的安全阈值,当任意监测值超出设置范围时,系统立即启动声光报警功能,及时提醒现场人员采取应对措施;同时,系统通过 OLED 显示屏实时显示各项监测数据,方便现场人员直观查看;此外,监测到的所有环境数据还能通过 WiFi 模块(ESP8266-12F)传输到手机端,实现远程实时监控,让管理人员随时随地掌握井下环境状况。

该煤矿环境监测及预警系统的作用在于,为煤矿安全生产提供了一种全方位、便捷高效的环境监测工具。通过对瓦斯、温湿度、粉尘、风速、风向等关键参数的实时监测、本地显示、远程传输及异常报警,能够帮助管理人员和现场矿工尽早发现环境安全隐患,及时采取针对性措施消除风险,有效降低煤矿安全事故发生概率,保障矿工生命安全,维护煤矿生产的稳定有序,提升煤矿安全生产管理水平。

关键词:STM32 单片机;煤矿环境监测;预警系统;多参数监测;WiFi 传输

Coal mine environment monitoring and early warning system based on STM32 microcontroller

Abstract

With the continuous expansion of coal mining scale and the increasing awareness of safety production, real-time monitoring and early warning of underground environmental parameters in coal mines have become a key link in ensuring the safety of miners’ lives and production stability. If the gas concentration in coal mines exceeds the standard, the temperature and humidity are abnormal, the dust concentration is too high, and the wind speed and direction are not suitable, if not monitored and handled in a timely manner, it may cause serious safety accidents such as explosions, poisoning, dust hazards, and even cause significant casualties and property losses. Therefore, it is necessary to develop a system that can monitor multiple parameters of the coal mine environment in real time and accurately, and has warning functions.

This design proposes a coal mine environment monitoring and early warning system based on STM32F103C8T6 microcontroller. The main functions of the system include: real-time monitoring of underground gas concentration through MQ-4 sensors to ensure the avoidance of gas explosion risks; Using DHT11 sensors to detect the temperature and humidity of the current environment, preventing abnormal temperature and humidity from affecting equipment operation and miners’ health; Monitor dust concentration through GP2Y1014AU sensor to reduce the harm of dust to miners’ respiratory system; Using a wind speed module consisting of a small DC brushed motor and a three cup rotating wind cup to monitor the current environmental wind speed and ensure good ventilation conditions underground; Monitor the current environmental wind direction through a Gray code wind direction sensor to assist in determining the direction of underground airflow; Users can set safety thresholds for various environmental parameters through buttons. When any monitoring value exceeds the set range, the system immediately activates the sound and light alarm function to remind on-site personnel to take corresponding measures in a timely manner; At the same time, the system displays various monitoring data in real-time through OLED display screens, making it convenient for on-site personnel to visually view; In addition, all monitored environmental data can be transmitted to the mobile phone through the WiFi module (ESP8266-12F) to achieve remote real-time monitoring, allowing management personnel to grasp the underground environmental conditions anytime and anywhere.

The role of the coal mine environmental monitoring and early warning system is to provide a comprehensive, convenient and efficient environmental monitoring tool for coal mine safety production. By real-time monitoring, local display, remote transmission, and abnormal alarm of key parameters such as gas, temperature and humidity, dust, wind speed, and wind direction, it can help management personnel and on-site miners detect environmental safety hazards as early as possible, take targeted measures to eliminate risks in a timely manner, effectively reduce the probability of coal mine safety accidents, ensure the safety of miners’ lives, maintain stable and orderly coal mine production, and improve the level of coal mine safety production management.

Keywords:STM32 microcontroller; Coal mine environmental monitoring; Early warning system; Multi parameter monitoring; WiFi transmission

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 瓦斯浓度检测模块电路设计

3.4 温湿度检测模块电路设计

3.5 粉尘浓度检测模块电路设计

3.6 风速检测模块电路设计

3.7 风向检测模块电路设计

3.8 显示模块电路设计

3.9 按键模块电路设计

3.10 声光报警模块电路设计

3.11 WiFi 传输模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 OLED显示流程设计

4.5 瓦斯检测模块子流程设计

4.6 温湿度检测模块子流程

4.7 PM2.5检测模块子流程设计

4.8 风速检测模块子流程设计

4.9 风向检测模块子流程设计

4.10 WiFi模块子流程设计

5 实物制作与功能测试

5.1 实物制作

5.2 多参数监测及 OLED 显示功能测试

5.3 阈值设置及声光报警功能测试

5.4 WiFi 数据传输功能测试

5.5 风向识别功能专项测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!