设计说明书

总字数:23000+

摘要

随着养殖业规模化、智能化发展,鸡舍环境参数的精准调控与养殖流程的自动化管理,成为提升养殖效率、保障鸡群健康的关键环节。鸡舍内温湿度失衡、有害气体超标、光照不足或喂食喂水不及时,易导致鸡群免疫力下降、生长缓慢,甚至引发疾病传播,造成经济损失。传统鸡舍依赖人工巡检与操作,存在监测不及时、调控精度低、人力成本高的问题,因此,研发一套能自动监测、智能调控且支持远程管理的智能鸡舍系统具有重要现实意义。

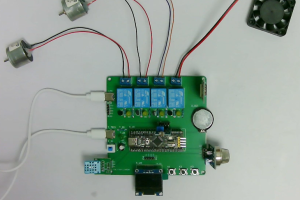

本设计提出了一种基于 STM32F103C8T6 单片机的智能鸡舍系统。系统核心功能包括:通过 DHT11 传感器检测鸡舍内温湿度,当温度或湿度高于预设上限值时,驱动继电器启动通风设备;通过 MQ-135 传感器检测有害气体浓度,当浓度超过预设最大值时,自动开启通风设备;借助 RTC 内部时钟设定开灯时间区,结合 5516 光照检测模块采集光照值,当光照值低于预设最小值且处于开灯时间区内时,通过继电器启动补光设备;用户可通过按键修正时间、设置温湿度上限、光照最小值、气体最大值及开灯时间区,还能手动控制通风、补光、喂食(继电器驱动)、喂水(继电器驱动)设备,并切换系统工作模式;通过 OLED 显示屏实时显示温湿度、有害气体浓度、光照值、时间及设备运行状态;借助 ESP8266-12F WIFI 模块将测量数据传输至手机端,用户也可通过手机端远程控制通风、补光、喂食、喂水设备及切换系统模式。

该智能鸡舍系统的作用在于,为养殖业提供了一套自动化、智能化的鸡舍管理方案。通过实时监测与自动调控,保障鸡舍内环境稳定适宜;远程控制与数据传输功能,减少人工干预成本,实现养殖流程的高效管理;同时,规范的喂食喂水控制,有助于提升鸡群生长质量,最终为养殖用户降低成本、提高经济效益,推动养殖业智能化发展。

关键词:STM32F103C8T6;智能鸡舍;环境监测;自动调控;WIFI 远程控制

Design and Implementation of Intelligent Chicken House Based on STM32

Abstract

With the development of large-scale and intelligent aquaculture, precise control of chicken coop environmental parameters and automated management of breeding processes have become key links in improving breeding efficiency and ensuring the health of chicken flocks. Imbalance of temperature and humidity, excessive harmful gases, insufficient lighting, or untimely feeding and watering in the chicken coop can easily lead to weakened immunity, slow growth, and even disease transmission in the flock, resulting in economic losses. Traditional chicken coops rely on manual inspection and operation, which leads to problems such as untimely monitoring, low regulation accuracy, and high labor costs. Therefore, developing an intelligent chicken coop system that can automatically monitor, intelligently regulate, and support remote management is of great practical significance.

This design proposes an intelligent chicken coop system based on STM32F103C8T6 microcontroller. The core functions of the system include: detecting the temperature and humidity inside the chicken coop through DHT11 sensors, and when the temperature or humidity exceeds the preset upper limit value, driving the relay to activate the ventilation equipment; Detect harmful gas concentration through MQ-135 sensor, and automatically turn on ventilation equipment when the concentration exceeds the preset maximum value; Using the RTC internal clock to set the lighting time zone, combined with the 5516 lighting detection module to collect lighting values, when the lighting value is below the preset minimum value and within the lighting time zone, the supplementary lighting device is activated through a relay; Users can adjust the time, set the upper limit of temperature and humidity, the minimum light value, the maximum gas value, and the time zone for turning on the lights through buttons. They can also manually control ventilation, supplementary lighting, feeding (relay driven), water feeding (relay driven) equipment, and switch the system working mode; Real time display of temperature and humidity, harmful gas concentration, lighting value, time, and equipment operation status through OLED display screen; By using the ESP8266-12F WIFI module to transmit measurement data to the mobile phone, users can also remotely control ventilation, lighting, feeding, water feeding equipment, and switch system modes through the mobile phone.

The function of this intelligent chicken coop system is to provide an automated and intelligent chicken coop management solution for the breeding industry. By real-time monitoring and automatic regulation, ensure a stable and suitable environment inside the chicken coop; Remote control and data transmission functions reduce manual intervention costs and achieve efficient management of the breeding process; Meanwhile, standardized feeding and water control can help improve the growth quality of chicken flocks, ultimately reducing costs and increasing economic benefits for breeding users, and promoting the intelligent development of the breeding industry.

Keywords:STM32F103C8T6; Intelligent chicken coop; Environmental monitoring; Automatic regulation; WIFI remote control

目 录

1 绪论

1.1 研究背景及意义

1.2 国内外研究现状

1.3 主要内容

2 系统总体方案设计

2.1系统总体设计

2.2 主要模块方案选择

3 系统硬件设计

3.1 总体硬件框架

3.2 主控模块电路设计

3.3 环境检测模块电路设计

3.4 执行控制模块电路设计

3.5 人机交互模块电路设计

3.6 通信模块电路设计

3.7 RTC 时钟模块电路设计

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 温湿度检测模块子流程

4.5 光照检测模块子流程设计

4.6 有害气体检测模块子流程设计

4.7 OLED显示流程设计

4.8 WiFi模块子流程设计

5 实物制作与功能测试

5.1 实物制作

5.2 温湿度与有害气体检测及通风控制功能测试

5.3 RTC 时间与光照联动补光功能测试

5.4 按键参数设置与手动控制功能测试

5.5 喂食喂水控制功能测试

5.6 WIFI 远程通信与控制功能测试

5.7 系统综合功能测试

6 总结

参考文献

致谢

附录A 原理图

附录B PCB

附录C 主程序

购买后可查看具体内容!