设计说明书

总字数:13000+

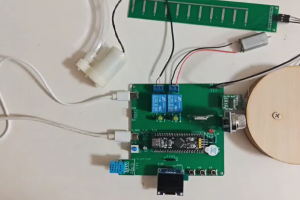

摘要:随着科技的发展和人们生活水平的提高,对鸡舍养殖业的要求也越来越高。传统鸡舍的养殖方式往往依赖于人工监控,不仅耗费大量人力物力,而且难以实现实时精确的控制。因此,开发一款智能喂食系统具有很高的实用价值。这款基于STM32F103C8T6单片机的智能环境检测系统,不仅能够实现对环境的实时监测,还可以通过远程控制实现喂水和喂食的操作,大大提高了鸡舍养殖业的效率。同时,系统还具有环保和安全的特点,有助于提高养殖环境的健康性,降低养殖风险。当水位低于预设的最小值时,系统会自动启动加水泵,将水位调整至最大值。压力传感器模块设计:压力传感器HX711用于检测喂食系统中的实物重量,当实物重量低于预设的最小值时,系统会自动启动加食物装置,增加食物重量,直至达到预设的最大值。为了确保食物的均匀添加,通过四个按键,分别用于设置温湿度、氨气浓度、液位和食物重量的阈值。通过这四个按键,用户可以根据实际需求调整各参数阈值,实现对环境的精准控制。OLED液晶显示屏模块设计:OLED液晶显示屏用于显示实时检测数据,包括温度、湿度、氨气浓度、液位和食物重量等信息。通过直观的显示,用户可以随时了解环境状况,并根据需要进行调整。WiFi模块设计:WiFi模块将检测数据传输到手机端,用户可以通过手机端查看环境数据,并设置参数阈值。为了确保数据传输的稳定性和安全性。同时,手机端还提供了远程控制功能,方便用户随时随地控制喂水和喂食。通过以上各模块的设计与实现,这款基于STM32F103C8T6单片机的智能喂食系统不仅能满足用户对环境监测的需求,还能实现远程控制,为用户提供便捷的操作体验。在未来,我们相信这款系统将在养殖业等领域得到广泛应用,为用户提供高效、智能的喂食管理方案。

关键词:鸡舍环境;远程测控;温湿度;氨气;液位;重量

Design of indoor chicken farming environment monitoring system based on STM32

Abstract: With the development of technology and the improvement of people’s living standards, the requirements for the chicken coop breeding industry are also increasing. The traditional chicken coop farming method often relies on manual monitoring, which not only consumes a lot of manpower and material resources, but also makes it difficult to achieve real-time and accurate control. Therefore, developing an intelligent feeding system has high practical value. This intelligent environment detection system based on the STM32F103C8T6 microcontroller can not only achieve real-time monitoring of the environment, but also remotely control the operation of water and feeding, greatly improving the efficiency of the chicken coop breeding industry. At the same time, the system also has the characteristics of environmental protection and safety, which helps to improve the health of the breeding environment and reduce breeding risks. When the water level drops below the preset minimum value, the system will automatically start the water pump and adjust the water level to the maximum value. Pressure sensor module design: The pressure sensor HX711 is used to detect the actual weight in the feeding system. When the actual weight is lower than the preset minimum value, the system will automatically start the food adding device to increase the weight of the food until it reaches the preset maximum value. To ensure even addition of food, four buttons are used to set thresholds for temperature and humidity, ammonia concentration, liquid level, and food weight. Through these four buttons, users can adjust the threshold values of various parameters according to their actual needs, achieving precise control of the environment. OLED LCD Display Module Design: OLED LCD displays are used to display real-time detection data, including temperature, humidity, ammonia concentration, liquid level, and food weight information. Through intuitive display, users can always understand the environmental conditions and make adjustments as needed. WiFi module design: The WiFi module transmits detection data to the mobile end, allowing users to view environmental data and set parameter thresholds through the mobile end. To ensure the stability and security of data transmission. At the same time, the mobile phone also provides remote control function, making it convenient for users to control water and feeding anytime and anywhere. Through the design and implementation of the above modules, this intelligent feeding system based on the STM32F103C8T6 microcontroller can not only meet the needs of users for environmental monitoring, but also achieve remote control, providing users with a convenient operating experience. In the future, we believe that this system will be widely applied in fields such as animal husbandry, providing users with efficient and intelligent feeding management solutions.

Keywords: Chicken coop environment; Remote measurement and control; Temperature and humidity; Ammonia gas; Liquid level; weight

目 录

1 绪论

1.1研究背景与意义

1.2国内外发展历程

1.3研究目标及预期功能

2 设计思路与方案选择

2.1整体设计方案

2.2 主要元器件选择

2.1.1 主控模块方案选择

2.1.2温湿度检测模块方案选择

2.1.3 称重模块方案选择

2.1.4 显示模块方案选择

2.1.5 无线传输模块选择

3 硬件设计

3.1主控电路模块

3.2 温湿度检测模块电路

3.3 氨气检测模块电路

3.4液位检测模块电路

3.5 压力检测模块电路

3.6 显示模块电路

3.7 继电器模块电路

3.8 声光报警模块电路

3.9 独立按键模块电路

3.10 WiFi模块电路

4 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 独立按键

4.4 温湿度检测模块子流程

4.5 OLED显示流程设计

4.6 WiFi模块子流程设计

5 实物测试

6.1整体实物测试

5.2温湿度检测实物测试

5.3 氨气浓度检测实物测试

5.4 液位检测实物测试

5.5 实物重量检测实物测试

5.6 远程测控实物测试

结论

致谢

参考文献

附录

附录一 原理图

附录二 PCB

附录三 主程序

购买后可查看具体内容!