设计说明书

总字数:17000+

摘要

在寒冷季节,取暖设备的稳定运行与安全控制对提升生活舒适度和保障使用安全至关重要。传统的加热取暖方式常存在温度控制精度低、缺乏实时监测与自动保护机制等问题,不仅能耗较高,还可能因压力异常、水位不足等引发安全隐患,难以满足智能化、安全化的使用需求。

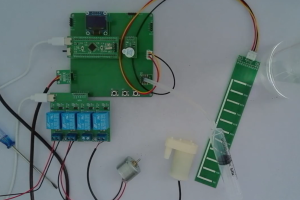

基于 STM32F103C8T6 单片机的半导体加热取暖应用设计,整合了防水式 DS18B20 温度传感器、XGZP6847 压力传感器、YW-J 水位监测模块、3 个独立按键、OLED 显示屏及执行设备(半导体加热模块、水泵、泄压阀继电器、加水继电器等),实现了加热过程的自动化控制与安全监测。系统核心功能包括:通过 DS18B20 实时监测温度,当温度低于最小值时启动半导体加热模块,高于最大值时停止加热,且水温高于最小值时开启水泵进行水循环,若监测到水位为 0 则立即停止加热;通过 XGZP6847 检测锅炉压力,高于最大值时打开泄压阀继电器;借助 YW-J 水位监测模块监控水位,低于最小值时开启加水继电器,直至水位高于最大值;支持通过 3 个独立按键设置各参数阈值、控制各继电器开关;通过 OLED 显示屏实时显示温度、压力、水位等测量数据及设备运行状态。

该设计的实现,有效提升了半导体加热取暖设备的自动化控制水平与安全性能,减少了人工干预,确保了温度、压力、水位等参数的稳定与安全,为冬季取暖提供了高效、可靠的解决方案,同时为同类加热设备的智能化研发提供了参考,具有较高的实际应用价值。

关键词:STM32F103C8T6;半导体加热;取暖应用;传感器;自动控制;安全监测

ABSTRACT

In cold seasons, the stable operation and safe control of heating equipment are crucial for improving living comfort and ensuring usage safety. Traditional heating methods often have problems such as low temperature control accuracy, lack of real-time monitoring and automatic protection mechanisms. They not only consume high energy but also may cause safety hazards due to abnormal pressure, insufficient water level, etc., making it difficult to meet the intelligent and safe usage needs.

The semiconductor heating application design based on the STM32F103C8T6 microcontroller integrates waterproof DS18B20 temperature sensor, XGZP6847 pressure sensor, YW-J water level monitoring module, 3 independent buttons, OLED display and executive devices (semiconductor heating module, water pump, pressure relief valve relay, water adding relay, etc.), realizing automatic control and safety monitoring of the heating process. The core functions of the system include: real-time temperature monitoring through DS18B20, starting the semiconductor heating module when the temperature is lower than the minimum value, stopping it when higher than the maximum value, and turning on the water pump for water circulation when the water temperature is higher than the minimum value, and immediately stopping heating if the water level is detected to be 0; detecting boiler pressure through XGZP6847, opening the pressure relief valve relay when it is higher than the maximum value; monitoring the water level with YW-J water level monitoring module, starting the water adding relay when it is lower than the minimum value until the water level is higher than the maximum value; supporting the setting of various parameter thresholds and controlling each relay switch through 3 independent buttons; real-time display of temperature, pressure, water level and other measurement data and equipment operation status through the OLED display.

The implementation of this design effectively improves the automatic control level and safety performance of semiconductor heating equipment, reduces manual intervention, ensures the stability and safety of parameters such as temperature, pressure and water level, provides an efficient and reliable solution for winter heating, and also offers a reference for the intelligent research and development of similar heating equipment, with high practical application value.

Keywords: STM32F103C8T6; Semiconductor heating; Heating application; Sensor; Automatic control; Safety monitoring

目录

第 1 章 绪论

1.1 研究的目的及意义

1.2 国内外发展情况

1.3 本文主要研究内容

第2章 设计思路与方案论证

2.1 主要元器件选择

2.1.1 主控芯片选择

2.1.2 温度传感器选择

2.1.3 压力传感器选择

2.1.4 水位监测模块选择

2.1.5 按键模块选择

2.1.6 显示模块选择

2.2整体设计方案

第 3 章 硬件设计

3.1 主控电路模块

3.2 温度传感器电路

3.3 压力传感器电路

3.4 水位监测模块电路

3.5 按键模块电路

3.6 显示模块电路

3.7 执行设备驱动电路

第4章 系统程序设计

4.1 编程软件介绍

4.2 系统主流程设计

4.3 OLED显示子流程设计

4.4 独立按键子流程设计

4.5 ADC模数转换子流程设计

4.6 温度检测模块子流程设计

第 5 章 仿真测试

5.1 整体仿真测试

5.2 温度传感器功能测试

5.3 压力传感器功能测试

5.4 水位监测模块功能测试

5.5 按键设置与显示功能测试

第 6 章 实物测试

6.1 整体实物测试

6.2 温度传感器功能测试

6.3 压力传感器功能测试

6.4 水位监测模块功能测试

6.5 按键设置与显示功能测试

第 7 章 总结与展望

7.1 总结

7.2 展望

致谢

参考文献

附录

附录一:原理图

附录二:PCB

附录三:主程序

购买后可查看具体内容!